CANNON RAFt™ SYSTEM

Cannon Raft

RAISED ACCESS FLOOR TECHNOLOGY

A RAFtTM is an installation frame which is used under a cabinet, in place of a floor tile, in raised floor installations, to provide extensive benefits.

ADVANTAGES & BENEFITS

- The RAFt™ sits on the pedestal heads integrating into the raised floor installation

- RAFts are bayed, just like cabinets

- Saves cost when compared to old fashioned installation methods

- Saves considerable installation time

- No tile cutting needed – saving further cost and mess

- Provides massive cable entry through base

- Base airflow is exceptional but may be sealed with Cannon brush gland

- Secures cab to pedestal system avoiding the need for tie bars to the floor substrate

- Lateral movement of raised floor installation becomes more rigid

- Allows minimised aisle widths and avoids cut tiles in aisle even for 1000mm deep cabinets as tiles in aisle slide under cabinet

- Tiles in aisle can be raised because of the resulting clearance from the raised cabinet base (cabinet sits 50mm above tile surface)

- RAFt™ accessories include brackets for commando connectors enabling power connections at RAFt™ level avoiding the need to enter floor void for power connection to PDUs etc

Saves pedestal costs, no tile cutting, quicker install, simplifies planning.

Avoids the need for intermediate pedestals. Only 600mm pitch pedestals are required, as no cut tiles means no intermediate pedestals

The Cannon RAFt™ System is compatible with the majority of Raised Access Floors with a modular tile size of 600mm x 600mm in current use worldwide.

Installation of the Cannon RAFt™ System is very simple as the system is designed to replace complete floor tiles in Raised Access Flooring where Cannon cabinets are to be installed.

RAFt™ Depth

The RAFt™ consists of a series of individual ‘picture frames’ which are bolted together and which always have the same depth (front-to-back) dimension as a floor tile (600mm). Cabinets with a depth (front-to-back) dimension greater than 600mm, overhang the RAFt™ equally at front and rear, i.e. a 1000mm cabinet would overhang the RAFt™ by 200mm at the front and rear or may be offset/aligned with front of cabinet or rear.

However, the RAFt™ raises the cabinet above the floor sufficiently to allow the overhanging tiles to be raised vertically and slid sideways for access to the under floor void.

for Air Flow Management and Maximum Cable entry see Full Brush Gland Frame or Brush and Plate Gland Frame Cable Entry

for Air Flow Management and Maximum Cable entry see Full Brush Gland Frame or Brush and Plate Gland Frame Cable Entry

CANNON RAFt™ SYSTEM

RAFt SYSTEM 600, 700 & 800 wide versions

RAFt Width

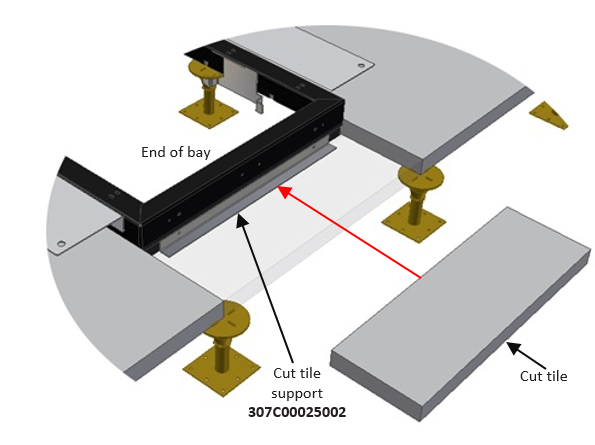

It is preferable that the frame width matches the cabinet width (600, 700 or 800mm). A 700 wide or 800 wide RAFt is laid out in the same manner as the 600 wide RAFt except from the position of clamp brackets and the end of raft position. Where a RAFt is built up from a multiple of frame widths other than the tile modular width of 600mm, it is likely that a part tile will be needed to act as a ‘filler’ at the end of the bay. A bracket is available (Order code: 307C00025002 cut tile support ) which bolts to the end of the RAFt to support this part tile. However, installers should check with the flooring manufacturers as to whether extra pedestals are also required to maintain the integrity /warranty of the floor system.

RAFt Brackets

RAFt Stringer Clamp

Individual clamps for use with floor stringers which hook under the stringers to prevent cabinet tipping. Four clamps per cabinet recomended, one in each corner. However, if the cabinets are securely bayed together one clamp may be used at the front and the rear. The end cabinets should still have four clamps each.

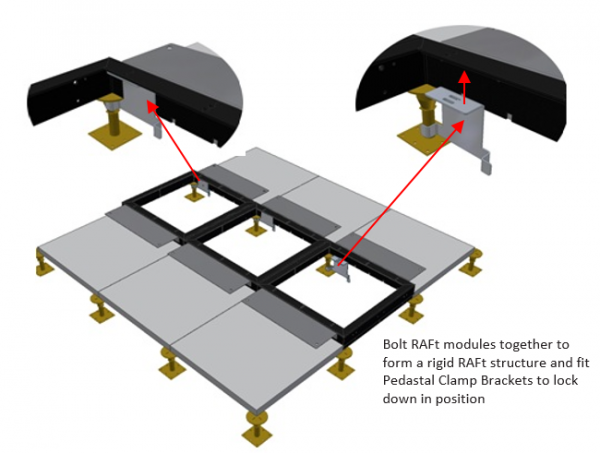

RAFt Pedestal Clamp

Single front and rear clamps for use when stringers are not present. These clamps are slotted for adjustment and clamp to the underside of the pedestal heads. Four clamps per cabinet recomended, one in each corner. However, if the cabinets are securely bayed together one clamp may be used at the front and the rear. The end cabinets should still have four clamps each.

RAFt Pedestal Clamp – 600 Centres

Double side clamps for use when stringers are not present. These clamps are slotted for adjustment and clamp to the underside of the pedestal heads. Two clamps per cabinet recomended, one on each side. However, if the cabinets are securely bayed together one clamp may be used. The end cabinets should still have two clamps each.

Order Codes

| CABINET WIDTH | PART CODE | |

| CABINET FOOTPRINT | CENTRAL MOUNT | REAR OVERHANG |

| 600 x 600 | 435B02606020 | - |

| 600 x 800 | 435B02608020 | 435B02608025 |

| 600 x 1000 | 435B02609920 | 435B02609925 |

| 600 x 1200 | 435B02601220 | - |

| 700 x 600 | 435B02706020 | - |

| 700 x 800 | 435B02708020 | 435B02708025 |

| 700 x 1000 | 435B02709920 | 435B02709925 |

| 700 x 1200 | 435B02701220 | - |

| 800 x 600 | 435B02806020 | - |

| 800 x 800 | 435B02808020 | 435B02808025 |

| 800 x 1000 | 435B02809920 | 435B02809925 |

| 800 x 1200 | 435B02801220 | - |

| DESCRIPTION | PART CODE |

| RAFt STRINGER CLAMP | 307C01200505 |

| RAFt PEDESTAL CLAMP | 307C11180500 |

| RAFt PEDESTAL CLAMP – 600 CENTRES | 307C12126003 |

| CUT TILE SUPPORT | 307C00025002 |